Sampling inspection method for metal stamping parts

Hardware stamping factory has strict inspection standards, which are divided into sampling inspection and all inspection.

Sampling inspection, also known as sampling inspection, is a statistical method and theory to randomly select a small number of products (samples) from a batch of products for inspection, so as to judge whether the batch of products are qualified or not. It is different from comprehensive inspection in that the latter needs to inspect the whole batch of products one by one and pick out the unqualified products, while sampling inspection infers the quality of the whole batch of products according to the inspection results of the products in the sample. If the inference result shows that the batch of products meets the pre-defined qualification standards, they will be accepted; Otherwise, it will be rejected. Therefore, a batch of products that are considered qualified through sampling inspection may also contain some unqualified products.

1、 Preparation for sampling inspection:

1). After the business contact list is issued, understand the production time / progress and preliminarily arrange the inspection time.

2). Know the factory and variety of production in advance, understand the general contents of the contract, be familiar with the production requirements and the quality requirements of our company, and be familiar with the inspection standards, requirements and key points of inspection.

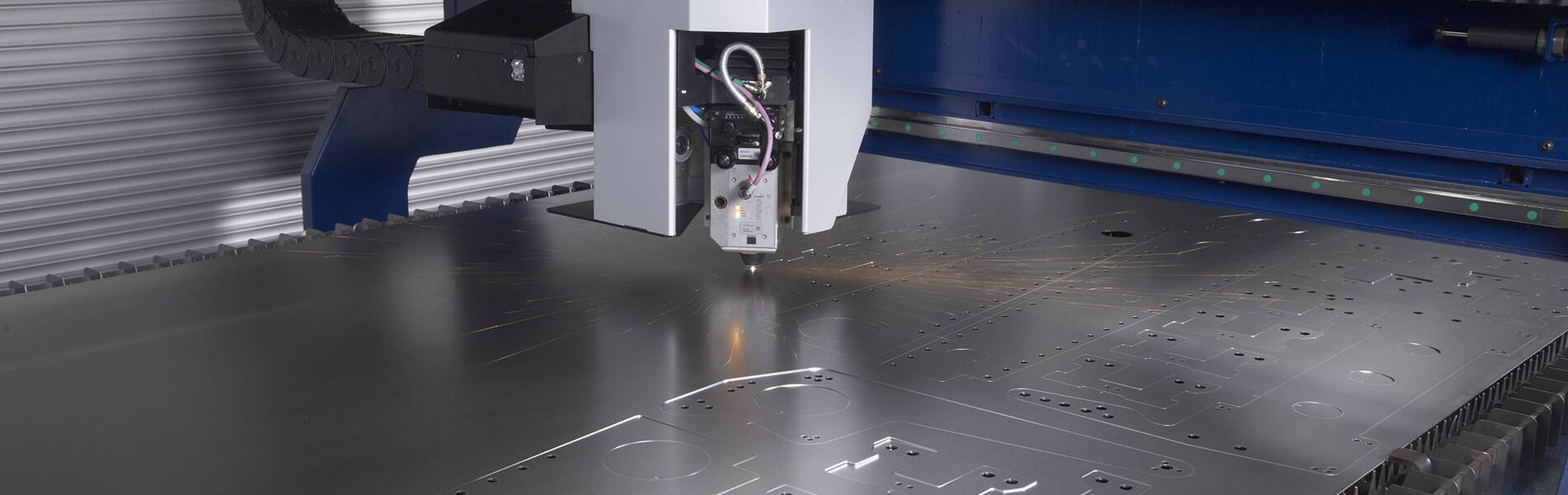

3). After understanding the general requirements, be aware of the main defects of the inspected goods. Such as scratches, burrs, deformation, spots and other defects of metal stamping parts. We should focus on the problems that are easy to occur, have flexible treatment methods, and be careful in cloth inspection.

4). Know when the big goods come out

© Copyright: 2024 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported