Stamping Process Analysis and Composite Die Design of LED Spot Lamp Holder

Stamping Process Analysis and Composite Die Design of LED Spot Lamp Holder

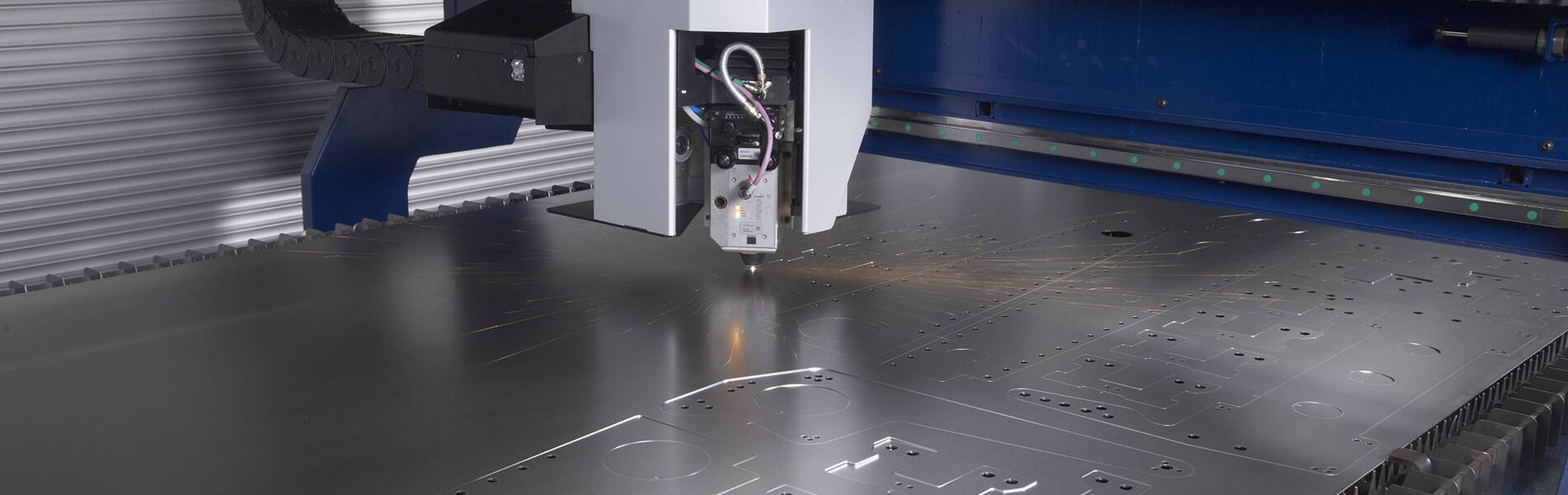

According to the structure and size of the LED spot lamp holder and the characteristics of aluminum raw material, the processing technology of its parts is analyzed.

To reduce the cost of raw materials, three sets of the die are designed: blanking, deep drawing and punching, side punching slot, and side drilling hole. A rubber block is installed on the punch of the blanking die, and through the elastic force of the rubber block, the cut aluminum plate is pushed away from the punch, which solves the problem of the aluminum plate sticking to the punch;

The aluminum plate is drawn and then punched, which solves the problem that the bottom hole is easy to burst after first punching and then flanging. The nut and thread mechanism are installed on the punch to make the punch move laterally and produce a rotating motion at the same time so that the side punch has the function of drilling.

The punching groove and drilling side hole are placed in the same set of mold, which can save the processing station.

Compared with aluminum rod turning, the cost of the new process is significantly reduced.

We invested a bit more budget in mold making, electronic components terminal stamping, and other precision metal stamping parts research and development technology. We strive to provide customers with more reliable technical support and product services.

We’ll be glad to offer you a quick reaction, if you need a reliable manufacturer that gives you your money’s worth, just contact us.

Previous :

Manufacturing Metal StampingNext :

Precise Stamping Parts Manufacture© Copyright: 2024 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported