Blog

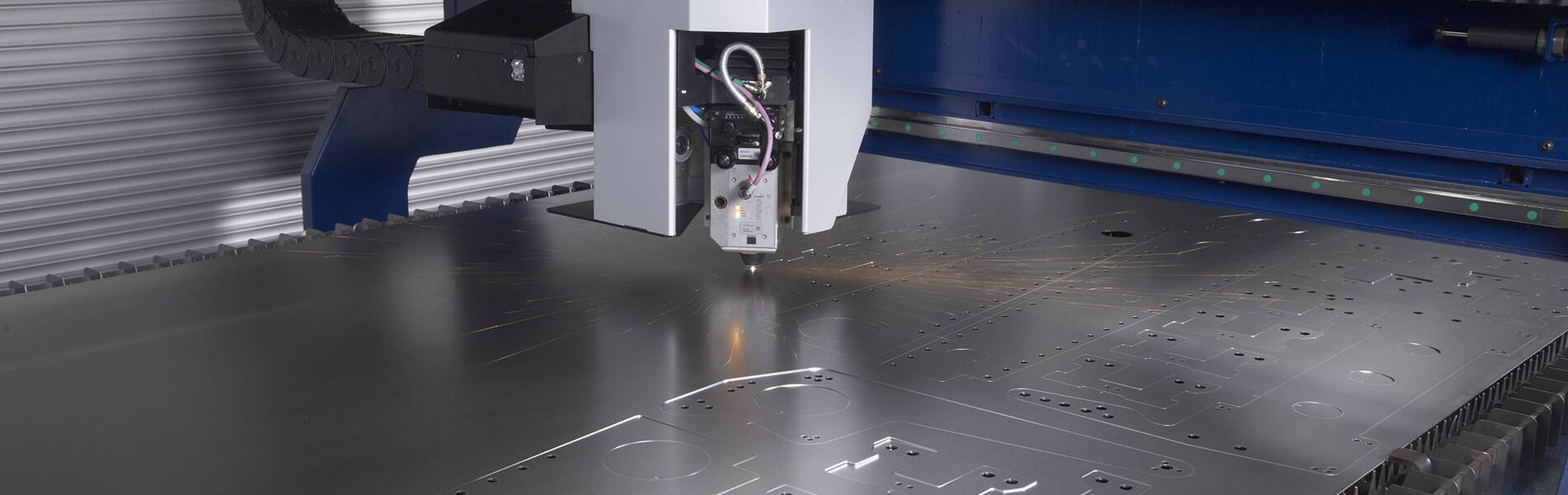

Usually, sheet metal is the material for the plate type, which is generally made into the specified shape and operated by the plate shearing machine or bending machine, while the machining is more complex. The material is massive, not simply bent and deformed, but cut, etc. the equipment generally uses lathes, grinding machines, etc

Why is the surface quality of metal stamping parts poor? There are many reasons for the surface quality problems of stamping parts. For example, the surface quality of coil, sheet and die will affect the quality of stamping parts. The operation in the stamping process and the clamping, taking and unloading of station instruments may also damage the surface quality of stamping parts. Therefore, the...

The design of metal stamping parts shall comply with the following rules: 1.The design of metal stamping parts must be simple in appearance and fair in structure, so as to simplify the die structure and the number of processes simplified by Guangdong metal stamping plant and Guangdong steel pipe plant, that is, complete the processing of the whole parts with the least and simplest stamping process...

1: Electroplating The process of attaching a metal film to the surface of metal by electrolysis to prevent corrosion A technology that can improve weldability, conductivity and beauty. Usually electroplated with gold, silver, nickel, zinc and tin. 2: Anodic oxidation It is mainly the anodizing of aluminum, which uses the electrochemical principle to generate a layer of alumina film on the surface ...

The processing of metal stamping parts is the requirements for bending parts: 1. The shape of bending parts shall be symmetrical as far as possible, and the bending radius shall not be less than the minimum bending radius allowed by the material. 2. The curved edge is too short and difficult to form, so make the straight part of the curved edge H > 2 δ。 If h is required to be very short, approp...

The quality standards of stamping parts are divided into national standard and non-standard. The following are different concepts about national standard and non-standard: National standard: refers to the standard approved and issued by the national standardization authority, which is of great significance to the national economic and Technological Development and is unified throughout the country...

The three most important steps in a stamping factory are shearing, punching / cutting and folding. Stamping parts are sometimes used as metal pulling. The word comes from English platemetal. Generally, some metal sheets are pressed by hand or die to produce plastic deformation to form the desired shape and size, and more complex parts can be formed by welding or a small amount of mechanical proces...

Product introduction: Material: stainless steel, red copper, phosphor copper, SECC, SGCC, SPCC, cold rolling, hot rolling Production process: press installation, specific die stamping, appearance treatment (electroplating, powder spraying, heat treatment, pickling passivation...

Metal processing plants often encounter burrs in metal stamping parts when producing metal stamping products. There are tools to remove the burr of metal stamping parts: 1. Hole: use a chamfering knife or the front end of a larger diameter drill bit 2. Edge: use file, oilstone, sandpaper, grindstone, 3. Welding slag: vibration slag removal tools can also remove brittle burrs 4. Outer diameter: gui...

Hardware stamping factory has strict inspection standards, which are divided into sampling inspection and all inspection. Sampling inspection, also known as sampling inspection, is a statistical method and theory to randomly select a small number of products (samples) from a batch of products for inspection, so as to judge whether the batch of products are qualified or not. It is different from co...

© Copyright: 2024 Jiaxin (Xiamen) Precise Metal Co.,Ltd. All Rights Reserved

IPv6 network supported